Ultrasonic Cleaning in Railway Maintenance

Efficient and effective cleaning is essential in the railway maintenance sector to ensure safe and reliable operations. Traditional cleaning methods can be time-consuming, labor-intensive, and may not achieve the desired level of cleanliness. However, ultrasonic cleaning technology has emerged as a game-changer, offering numerous advantages for railway maintenance. This essay explores the benefits of ultrasonic cleaning in railway maintenance, highlighting its impact on thorough cleaning, time and cost savings, non-destructive cleaning, enhanced safety and performance, extended equipment lifespan, and improved maintenance planning.

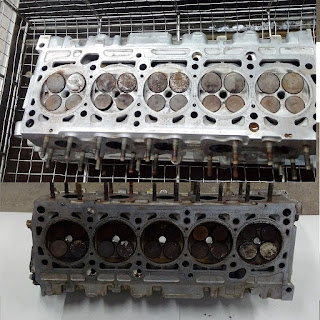

Thorough Cleaning:

Ultrasonic cleaning utilizes high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles implode near the surface of railway components, generating intense scrubbing action that effectively removes contaminants such as dirt, grease, oil, and rust. Unlike traditional methods, ultrasonic cleaning reaches intricate areas, crevices, and hard-to-reach spots, ensuring a thorough cleaning that enhances the overall cleanliness and reliability of railway equipment.

Time and Cost Savings:

Ultrasonic cleaning significantly reduces the time and effort required for railway maintenance tasks. The automated process allows for simultaneous cleaning of multiple components, improving productivity and reducing labor costs. By eliminating manual scrubbing and reducing the use of harsh chemicals, ultrasonic cleaning streamlines maintenance operations and optimizes resource utilization. The resulting time and cost savings contribute to increased efficiency and improved profitability in railway maintenance.

Non-Destructive Cleaning:

One of the critical advantages of ultrasonic cleaning is its non-destructive nature. Delicate and sensitive railway components, including electrical connections and equipment, are prone to damage from abrasive cleaning methods. Ultrasonic cleaning, however, offers a gentle yet powerful solution that effectively removes contaminants without causing harm. The process ensures the integrity and longevity of critical parts, minimizing the risk of equipment failures and costly replacements.

Enhanced Safety and Performance:

Clean railway components are vital for safe and efficient train operations. Ultrasonic cleaning removes dirt, debris, and contaminants that can compromise the performance and reliability of railway equipment. By maintaining a high level of cleanliness, ultrasonic cleaning helps prevent equipment malfunctions, reduces the risk of signal failures, and enhances the overall safety and performance of railway systems. This advantage contributes to increased passenger and operator safety, as well as improved service reliability.

Eco-Friendly Solution:

Ultrasonic cleaning is an environmentally friendly alternative to traditional cleaning methods. With lower water consumption, reduced chemical usage, and the use of biodegradable cleaning solutions, ultrasonic cleaning minimizes its environmental impact. This eco-friendly approach aligns with sustainability initiatives and reduces waste generation in railway maintenance operations. By adopting ultrasonic cleaning, railway maintenance professionals can contribute to a greener and more sustainable industry.

Extended Equipment Lifespan:

Regular cleaning with ultrasonic technology helps extend the lifespan of railway components and equipment. By removing corrosive substances, dirt, and grime, ultrasonic cleaning prevents the deterioration and degradation of critical parts. This reduces the frequency of repairs and replacements, leading to significant cost savings over the equipment's operational life. Ultrasonic cleaning serves as a proactive maintenance measure, preserving the integrity of railway equipment and optimizing asset management.

Improved Maintenance Planning:

Ultrasonic cleaning provides valuable data and insights during the railway maintenance process. By utilizing ultrasonic inspection devices, operators can assess the condition of components, detect hidden defects, and measure thicknesses. This information facilitates proactive maintenance planning, allowing for timely repairs or replacements and reducing the risk of unexpected failures or delays in train operations. Ultrasonic cleaning's role in predictive maintenance contributes to optimized maintenance schedules and improved operational efficiency.

Ultrasonic cleaning technology offers a range of advantages for railway maintenance, revolutionizing the cleaning process in the industry. From thorough cleaning to time and cost savings, non-destructive cleaning, enhanced.

What do you need to clean with Industrial Ultrasonic Cleaning Machine (youtube.com)

Enquiries please contact tom@caldofreddo.me or call ±971 52 5060 253

Comments

Post a Comment